Kevin Brown

New member

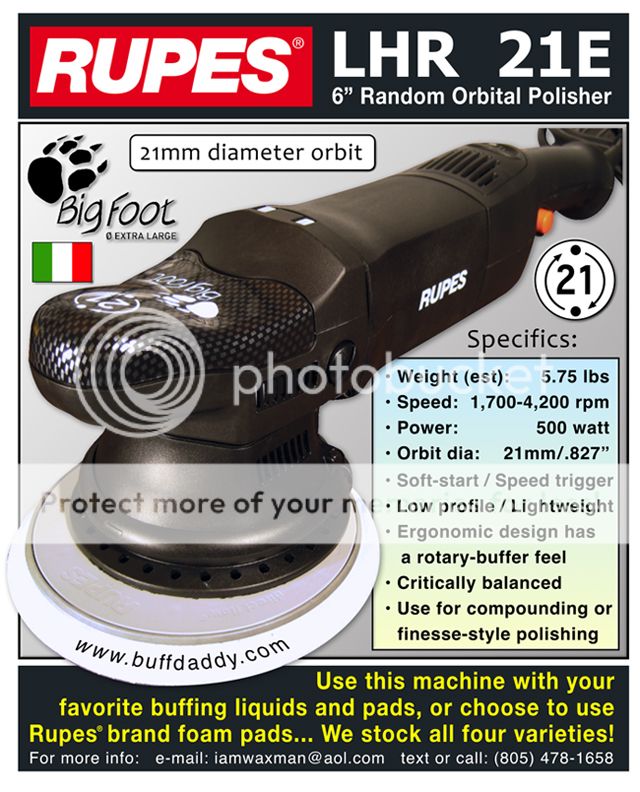

I have run the Rupes® LHR 21ES Random Orbital Polisher (herein referred to as Bigfoot) through its paces. As expected, it performs wonderfully! I am looking forward to selling the trio of Bigfoot-branded products (the LHR 15ES, LHR 21ES, and LHR 75).

This write-up is essentially a brief, outlining my thoughts about the Bigfoot. I have also included information regarding some of the latest products and techniques being used with random orbital polishers today, and a bit about how their popularity came about. My hope is that after reading this document, you will better understand why I appreciate the development of the Rupes® LHR 21ES so much.

Bigfoot Versus the Competition.

Bigfoot's price point is expected to be high relative to other electric random orbital polishers, so it will likely face an uphill battle on the sales front if compared only to other electric random orbital machines. I wouldn't be overly concerned about this speculation though, because Bigfoot's capabilities and build quality will have it contending for the paint polisher's dollar whether they happen to be shopping for a random orbital, forced rotation orbital, or rotary-action machine.

Since many of the most popular forced rotation orbital and rotary machines typically sell for $200.00 to $525.00, the Bigfoot should have no problem stealing away dollars from other available brands. Some of the most popular polishing machines are:

Random Orbital Polishers

Meguiar's® G110v2 Professional Dual Action Polisher ($149 typical)

Griot's® Garage 10765 6" Random Orbital ($99-$149 typical)

Porter Cable® 7424XP 6" Random Orbital Polisher ($119-$149 typical)

Dual Mode Orbital Machines (switchable or forced rotation)

Flex® XC 3401 VRG Orbital Polisher ($299-$349 typical)

Festool® Rotex RO 150 FEQ ($525)

Makita® BO6040 ($261-$319 typical)

Bosch® 1250 DEVS ($239-269 typical)

Dynabrade® 61379/61384 Dual Action Buffing Head ($57-$140 typical)

Rotary Polishers

DeWalt® DWP849 ($167-$225 typical)

DeWalt® DWP849X ($179-$250 typical)

Makita® 9227C ($195-$253 typical)

Flex® PE 14-2-150 6" compact Variable Speed Polisher ($359-$399)

Flex® L3403 VRG Lightweight Rotary Polisher ($240-$299 typical)

Festool® RAP150 ($400)

Sales Potential of the BigFoot.

The potential for USA-based sales of the Bigfoot is immense. Veteran paint-polishers will surely consider adding the Bigfoot to their arsenal of machines, but I believe that people new to the polishing scene will as well. After all, the enthusiasts among this group tend to heed the advice given to them by experts in the field, and they’ve grown up accepting the fact that a random orbital is a very capable cutting and finishing machine.

Although most experts will not normally recommend a rotary polisher to a beginner for obvious reasons, they do not hesitate to recommend a forced rotation orbital or dual mode orbital machine. But, will the experts heartily recommend the easy to operate random orbital? A search of the forums for the answer to this question tells an interesting tale.

Within the past five years, the random orbital has gained acceptance as being a tool capable of removing sanding marks and harsh defects. It is also capable of final-polishing paint to the highest degree. Prior to this time, its correcting abilities were called in to question, especially when compared to what an expert could accomplish wielding the mighty rotary.

It was generally accepted throughout the high-end detailing scene that the random orbital would almost certainly create haziness upon an otherwise perfectly polished surface. In short, the random orbital was opined to be for weekend warriors, whereas the rotary was the only real choice for true paint correction. As such, most experts relegated the random orbital to one-step polishing duties, or for final waxing of light colored paints. I believe that lackluster results were not the fault of the machine, but rather were in large part caused by:

- Backing plates & buffing pads paired for the advancement of polishing safety, rather than for ultimate polishing performance.

- The use of buffing liquids optimized for hand or rotary application.

- Performance limitations of D/A specific buffing liquids (due to their design or the unavailability of technologically advanced abrasives).

- Procedural recommendations that were not properly vetted.

The topic of how to best optimize performance of the random orbital is one that I could write pages and pages on (and I have: link). To the original question, and more specifically in regards to the Bigfoot: Will polishing experts recommend a random orbital with as massive a stroke as the Rupes[SUP]®[/SUP]? I believe they will.

To back this claim, one need only look at the rising popularity of the Dynabrade[SUP]®[/SUP] 61379 Dual Action Buffing Head Kit (now available in kit form only as model 61384). This unit features a 3/8â€� spindle offset, and allows the user to choose between random orbital and rotary modes. Spindle offset is not adjustable, so rotary action is also off-center 3/8â€�, and therefore creates a 3/4" diameter stroke:

Dynabrade Dual Action Buffing Head. Mounted atop a Makita 9227C Rotary Polisher.

In March 2009, I wrote a small article about the 61379, which I posted on a few of the more popular detailing forums. Not too many forum guys jumped at the chance to try this tool, primarily because it appeared to be heavy and bulky. Besides- it cost as much money to buy the 61379 as it would a typical random orbital machine.

This component, designed to mount to a rotary polisher, originally sold for $115.00-$145.00. For reasons unknown to polishing enthusiasts, Dynabrade[SUP]®[/SUP] decided to sell these units via their own online discount store for the incredible price of $59.00.

Dynabrade[SUP]®[/SUP] has recently introduced the 61318 Dynalocke[SUP]®[/SUP] Sanding Head, a rotary-mount unit that features true rotary action, and converts to a 3/16â€� stroke random orbital ($157.00). Perhaps this all-new unit was the reason for the price decrease on the 61379. Could there be an all-new large stroke buffing head on the way?

Regardless, once the prices dropped on the 61379’s and 61384’s, guys started purchasing them at a rapid pace. The buffing heads are being mounted to all sorts of rotary polishers, ranging in price from $39.00 (Harbor Freight) to over $500.00 (Fein[SUP]®[/SUP] 12-27E). Not only have the 61379’s gained acceptance, they’re now being used to polish some of the most expensive cars available today. Case in point: Three top-tier detailers polish a McLaren MP4-12C (link):

Attack of the Dynabrade Dual Action Buffing Head- McLaren MP4-12C:

Barry Theal, Eric Witt, and Dave Purser (January, 2012).

All three chose to use a long-stroke random orbital to polish the McLaren.

This is fantastic news for Bigfoot users, because it will outperform the 61379 (when used in random orbital mode), as its maximum recommended speed is 3,200 RPM. If the same arm speed is used to move both machines along, 31.25% more actual polishing of the surface will be accomplished using the Bigfoot, thanks to its 4,200 RPM capability.

Note: the 15mm-diameter stroke LHR 15ES features a 5,000 RPM top-end speed, which was likely bumped upwards to compensate for its inability to generate an equal amount of centripetal force (which is what makes the backing plate randomly rotate).

When used in forced rotation mode, the 61379 gains a performance edge over the Bigfoot assuming the goal of the polishing session is severe defect removal. However, the added RPM capability of the Bigfoot and larger stroke (21mm versus 19mm, or 10.5% more) help to negate this edge by creating more random rotation of the backing plate at maximum speed (perhaps as much as 10-14 turns per second when a spacer is placed between the mounting pad and backing plate).

There is no need for concern, because the Bigfoot has a huge advantage over the 61379 when comfort of use is taken into consideration. The Bigfoot is lighter, lower in height, and features a far superior balancing mechanism.

Not only will the comfort of the Bigfoot be a HUGE selling point against the 61379, it will be the deciding factor for people that would like to but literally cannot use a random orbital because of its inherent vibration. I must say- no currently available machine beats the Bigfoot when performance and comfort are taken into consideration.

The Bigfoot is incredibly well balanced.

Bigfoot is so well balanced, that I was able to control it using only one hand. This allowed me to use my other hand to apply additional polish, or mist the surface with water (to aid in extending the buffing cycle). Although this is not a technique I would recommend to others, it is an impressive feat nonetheless. While I am also able to accomplish this using traditionally designed random orbital machines, it is not at all easy to do.

The Bigfoot offers improved leverage over traditional designs.

Bigfoot offers more leverage due to its long length, giving it a feel similar to that of a traditional rotary polisher. Familiarity of the Bigfoot’s layout (speed setting, trigger, lock button, handle length, and ability to install a side mount or bail-style handle) will make rotary users feel right at home using the machine. The added length also means that minute unintended vertical movements of the handle will not transfer as readily to the head of the machine.

Length comparison: Rupes[SUP]®[/SUP] LHR 21E versus the Meguiar’s[SUP]®[/SUP] G110v2

The Rupes® LHR 21E measures 16-1/2â€�, not including the cord.

The added length increases leverage and comfort.

Rotary users will appreciate the familiar feel of the machine.

The Bigfoot features a low profile… 4-3/4� !

Bigfoot’s low profile increases its stability. If a guy is not careful when polishing, a tilt of the machine to the left or right can cause the pad to flip onto its side. It is rare but does happen, especially when using small-diameter pads or high operating speeds. Large stroke machines are more susceptible to this occurrence, especially when used to polish oddly shaped panels, or when the machine is tilted in hopes of allowing a smaller portion of the buffing pad to contact the paint surface.

Bigfoot’s low profile can also increase user comfort, and allow the machine to fit in confined areas (such as when trying to polish the dash area of a boat, directly behind a windshield or wind screen).

The Bigfoot’s low profile can improve high-speed stability.

To the left: the ever-popular Meguiar’s[SUP]®[/SUP] G110v2 Dual Action Polisher.

To the right: the Rupes[SUP]®[/SUP] LHR 21E Bigfoot Random Orbital Polisher.

The Bigfoot features a variable-speed trigger.

If this were the only feature distinguishing the Bigfoot from the rest of the pack, it would be enough to get me to make the switch to the Bigfoot! Luckily, this is not the case. Bravo on this point!

The Bigfoot is relatively lightweight.

Typical weight for a random orbital machine is approximately 5 pounds. The Bigfoot tips the scales at 6-1/2 pounds. Not bad, considering its added length, counterbalance mechanism, and hi-torque motor. This is still two to four pounds lighter than an industry standard rotary polisher outfitted with a Dynabrade[SUP]®[/SUP] Dual Action or Random Orbital Buffing Head.

The Bigfoot has tremendous cutting ability.

Isn’t this what it’s all about? Compared to a machine featuring a shorter stroke, the Bigfoot moves compounds and pads a farther distance for every rotation the backing plate, which means things are also moving at a more rapid clip. The extra motion and speed can cause abrasive particles to readjust as they move, effectively extending the buffing cycle. This is readily apparent to anyone that has used the 3" Air-Powered LHR75 Mini Random Orbital Polisher; its cutting ability is hard to believe, yet scouring of the surface is kept to a minimum.

The Bigfoot’s 21mm stroke creates loads of centripetal force at speed, and its spindle bearings allow the backing plate to spin along unabated. Consequently, random rotation of the backing plate should be out of this world! However, a purpose-built shroud not only covers the driveshaft-mounted rotating components, but also slows backing plate rotation via drag-induced friction.

Marco (the Rupes® engineer that developed the machine) explained that excessive rotation could cause scouring of the polishing surface if the backing plate and buffing pad were allowed to freewheel spin prior to contacting the polishing surface. He also mentioned that excessive rotation was considered to be a safety hazard in some parts of the world. Understanding his reasoning, I nevertheless decided to install a spacer between the backing plate and mounting pad in hopes of restoring a maximum amount of backing plate rotation.

A metal, plastic, or phenolic washer will work. Cut and sand to size.

The height of the spacer needs to be enough so that the backing plate will no longer contact Bigfoot’s shroud. The spacer shown is approximately 3/16� tall and was taken from a backing plate featuring a 5/16�-24 mounting stud.

The spacer was placed between the backing plate and mounting pad.

The pad still mounts safely and securely. If desired, a minimally longer bolt can be installed to compensate. The bolt is 8mm. The shape of the platform and spacer is known as a Double-D cutout.

The resultant gap is nearly unnoticeable.

With the spacer installed, backing plate rotation and cutting speed were dramatically increased.

The difference was apparent, even when low speed settings were used.

With the spacer installed, backing plate rotation increased immensely. While I was not able to verify exactly how big an increase occurred in terms of backing plate rotation or cutting power, I can say that it was a LOT. My best guess: backing plate rotation increased to 10-14 times per second, and cutting speed increased by about 50 percent.

If a rotary buffer outfitted with a wool pad had any sort of performance advantage over the Bigfoot, the advantage was nearly or completely negated after this easy to implement modification. This newfound cutting power elevates the Bigfoot to superstar status. I hope that Marco will not be overly upset by the addition of the spacer, and I am sure he is aware of the tremendous rotation potential of this machine (otherwise there would have been no need to design the shroud to contact the backing plate). Regardless, I plan on using my machine with a spacer installed.

Note: For the record, I used Meguiar’s[SUP]®[/SUP] M101 Foam Cutting Compound and Meguiar’s[SUP]®[/SUP] M105 Ultra-Cut Compound while conducting this test. The Bigfoot was outfitted with a Meguiar’s[SUP]®[/SUP] 6â€� DA Microfiber Finishing Disc.

Whereas a machine such as the Meguiar’s[SUP]®[/SUP] G110v2 Dual Action Polisher (8mm stroke, 6,800 OPM max) requires that a 5â€� DA Microfiber Disc be used in order to maximize polishing performance, the Bigfoot delivered equal or faster results using the 6â€� discs. Compared to a 5â€� disc, a 6â€� disc offers up more surface area, increased stability, longer working time, and higher rotational speed along the edge of the disc.

In the end, it’s likely that most guys won’t add a spacer between the backing plate and mounting pad. I’m not even aware of whether such a thing will cause a warranty issue. Regardless, as long as the balance or motion created by the Bigfoot is not negatively affected by the design or weight of the buffing pad, the Bigfoot will perform on par or better than a typical random orbital that has been outfitted with smaller diameter pads.

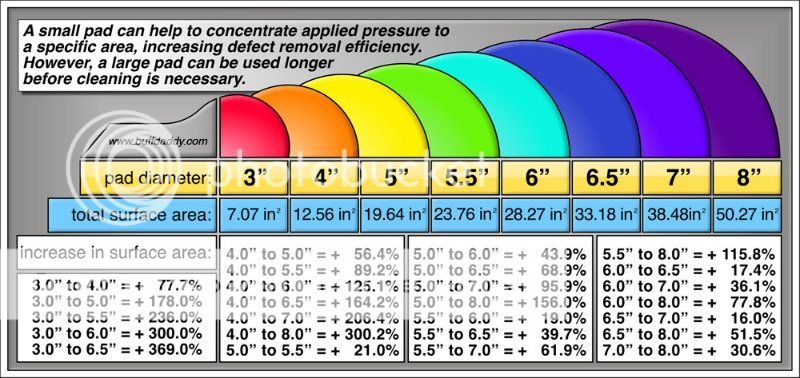

Pad Diameter Comparison Chart

Most paint polishing guys do not realize how big a difference pad diameter can make.

As an example, a 6� buffing pad features 43.9% more surface area than a similar 5� pad.

The Bigfoot can create a dazzling finish.

Although most guys will be surprised to know that a large stroke machine can create a sparkling, haze-free finish, I have thought this to be the case for years. It sure would have been nice to meet Marco three or four years ago, as I felt my thoughts about cutting and finishing using a large stroke machine had to be incorrect. As it turns out… they were not.

I have found that as long as a proper polishing technique is used and the following guidelines are adhered to, a fantastic finish can almost always be achieved.

A long stroke machine used with a low speed setting creates the ideal setup for the final polishing of any surface. While there may be some exceptions to this statement, the amount of exceptions is likely very low. I believe that the following data supports the premise (many of you may have seen this information before).

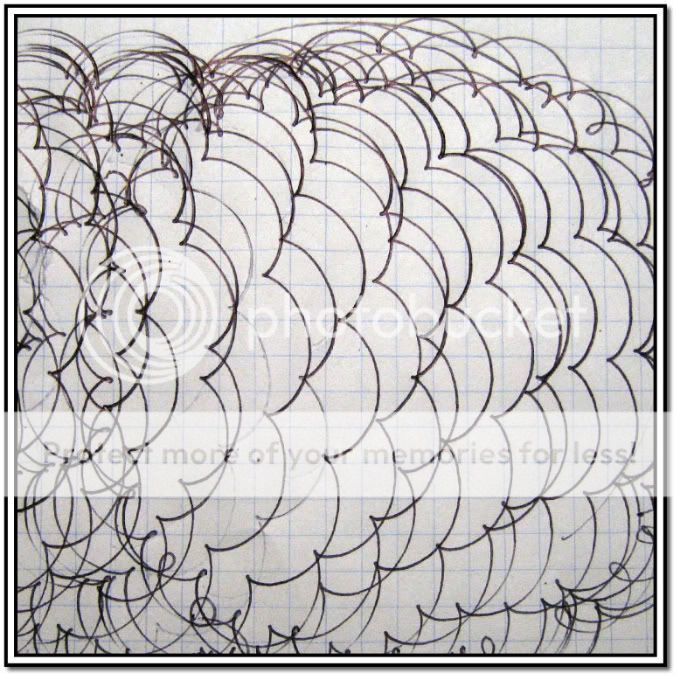

To better understand backing plate motion, I built this device.

[

[

To illustrate how oscillation speed, pad rotation, and user controlled movements affect the pattern created by a random orbital, a random orbital polisher was outfitted with a backing plate using four modified ballpoint pens in place of a buffing pad.

This particular machine (the Meguiar’s G110 Dual Action Polisher) creates a 5/16� (8mm) diameter stroke. However, the pattern it generates is dependent upon a large group of factors. Note: the circle created by the rotating pens measures 4-3/8� (111mm) in diameter.

I have found that as long as a proper polishing technique is used and the following guidelines are adhered to, a fantastic finish can almost always be achieved.

- Use the lowest speed setting that allows continuous but slow rotation of the backing plate (see diagrams below for clarification).

- Avoid angling the machine in a manner that causes the buffing pad’s edge to be driven into a panel’s surface.

- Make sure that backing plate rotation is never stalled, or excessively rapid.

- Keep the buffing pad clean (microfiber pads must be kept fluffy as well, in order to keep the fibers separated from each other).

A long stroke machine used with a low speed setting creates the ideal setup for the final polishing of any surface. While there may be some exceptions to this statement, the amount of exceptions is likely very low. I believe that the following data supports the premise (many of you may have seen this information before).

To better understand backing plate motion, I built this device.

To illustrate how oscillation speed, pad rotation, and user controlled movements affect the pattern created by a random orbital, a random orbital polisher was outfitted with a backing plate using four modified ballpoint pens in place of a buffing pad.

This particular machine (the Meguiar’s G110 Dual Action Polisher) creates a 5/16� (8mm) diameter stroke. However, the pattern it generates is dependent upon a large group of factors. Note: the circle created by the rotating pens measures 4-3/8� (111mm) in diameter.

This pattern was created using the machine on speed setting 1, which equates to 2,560 orbits per minute.

This pattern was created using speed setting 6, which equates to 6,700 orbits per minute.

The pen markings tell an interesting tale. When the machine was adjusted to speed setting 1, the pattern revealed a backing plate motion that was curlicue in shape at the orbit transition point (the small “loop� which forms as one orbit ends, and another begins). This pattern verifies that there was a smooth movement of the backing plate. However, as machine speed was increased to speed setting 6, the curlicue transition loop tightened, eventually creating a spiked point instead of a loop.

The net result of these patterns may be difficult to envision, but imagine if the blade of an ice skate created these lines as it traveled across an ice rink. Whereas the curlicue, slow speed pattern would show a smooth movement of the blade with little or no uneven gouging of the ice, the pointed, high-speed pattern would certainly create gouges in the ice at the transition points.

Upon consideration of the patterns, one might conclude that although a higher speed setting can increase cutting power or accomplish more work in a shorter period of time, the paint finish may suffer because of it. This is especially true when the random orbital is used to sand paint prior to polishing. Should gouges or deep pigtail marks occur during sanding (and excessive machine speed is determined to be the culprit), a lowering of the machine speed may reduce or prevent creation of the markings. Precise measuring of the pen marks help to validate the premise:

There’s more to this story!

Typically, a buffing pad can more readily contour to a panel shape if the pad is moving at a slow rate of speed. (this is true regardless the type of machine). However, a potentially BIG problem arises when a low speed setting is used with a random orbital: rotation of the backing plate suffers, especially if the machine features a short stroke. Things get even worse if the buffing pad is soft and pliable, because its cushioning action can absorb some or all of the machine’s motion, causing backing plate rotation to slow, or stall altogether. To combat stall, machine speed must be increased in hopes of restoring pad rotation via centripetal force. Unfortunately, repetitive scrubbing of the surface sans at this point can create micro marring, as the abraded paint residue saturates the buffing liquid and pad.

Pad stall won’t happen all that often with the Bigfoot, because its large stroke generates a massive amount of centripetal force (which is what makes the backing plate rotate in the first place). Consider that fact for a moment, and take into account the long and gradual sweeping motion created by the machine.

As the diagrams have shown, a slow speed setting creates a softly curved pattern, enabling the pad to easily contour, avoiding edge digging in the process. In addition, the abrasive particles instilled throughout the buffing liquid are scuttled along longer distances per oscillation with the Bigfoot, allowing said particles to adjust positioning as they move. This aids in keeping the particles clean, and helps to minimize clumping.

The Bigfoot works well with a variety of pads and liquids.

I spent quite a bit of time using a variety of buffing pads and liquids with the Bigfoot. While the supplied Rupes[SUP]®[/SUP] foam pads and buffing liquids worked very well, I was able to achieve impressive results using the Meguiar’s[SUP]® [/SUP]DA Microfiber System. I had expected this would be the case, as I have spent hundreds of hours using the discs and liquids in prototype and finalized forms.

Rupes[SUP]®[/SUP] pads and liquids were expected to work well with the Bigfoot.

I was able to achieve excellent results using other brands of pads and liquids as well.

Machine comfort was very good, regardless the pad.

Why am I so excited about the existence of the Bigfoot?

Bigfoot’s design is mechanically superior & wonderfully unique.

Although buffing liquids and pads are now being tailor made en masse specifically for use with random orbital polishers, machine manufacturers continue to plod along by mimicking the design of the ever-popular Porter Cable 7424.

As far as I know, Bigfoot is the first machine on the market to offer a rotary-style layout, variable-speed trigger, and a formidable 21mm stroke! This is 2.625 times larger than the typical 8mm industry-standard large stroke machine. The fact that a machine such as the Bigfoot was built at all vindicates my thoughts about machine stroke, which are outlined in an article I wrote (available here). Summarized, I believe that there are numerous benefits that come with using a large stroke machine.

Bigfoot is the machine that I’ve wanted AND needed… for years!

As a person that has worked for over two decades to become proficient using a rotary polisher, I’ve come to accept that due to the progression of technology (and a better understanding of how to optimize machines for maximum polishing performance), the random orbital is capable of delivering results that equal or surpass those created by a rotary.

This realization was slow in coming, but as I continued to spend time experimenting with the random orbital, I thought more about the mechanical aspects of the machine, shelving any preconceived notions of its abilities in the process. Whereas the philosophy of learning by doing had served me well in so many areas of detailing, advice given to me regarding the polishing process had not. So, why not learn by thinking about the mechanical aspects of the machine, as opposed to just using the machine and then analyzing results?

Taking thoughts of the mechanical process to extremes helped a lot. As an example, if I were pondering the effects of backing plate weight on random rotation, I would consider extremely light plates as well as extremely heavy plates, their diameters, densities, mass placement, and so on. I also gained knowledge through the testing of prototype products, and consequent discussions regarding those products. But, how best to share this newfound knowledge, without inadvertently sharing trade secrets?

An understanding of what was occurring at the mechanical level was key to writing explanations that would allow readers to create extraordinary polishing results, using already available products. What a difference this made; visualizing what was happening as opposed to wondering what might be occurring.

In closing.

I look forward to selling the Bigfoot and other Rupes[SUP]®[/SUP] products. The Bigfoot is not a perfect machine, but it comes close. It is apparent that the Bigfoot is a well thought out machine, and heartily built.

I am wondering if the weight distribution of the machine is a bit too forward biased. I cannot confirm this to be true, but this was the first time I recall ever having a strained feeling throughout the muscles of my forward-positioned hand. For now, I’ll chock this up to the fact that when this occurred, I had spent a couple hours polishing the side of my pickup truck, and I was running the machine through the ringer, swapping pads, and generally getting accustomed to the machine.

I see a great opportunity to sell a foam cushion or gel-filled hand pad. It could sit atop the head of the machine, and mount using the threaded holes that already exist for installation of either a side-mount or bail-style handle. I did not see that a handle of any type existed for the Bigfoot, but I suspect this was simply due to an omission in the literature.

Finally, I do not believe that the Bigfoot will be the best choice of machine for every job. On areas such as those that are unusually skinny, or for times when the area in need of polishing is in close proximity to delicate or protruding objects, or if polishing needs to be confined to a specific area, a small stroke random orbital or rotary machine may be a better choice:

All this being said… in most cases, I think the Bigfoot will be the machine that guys will reach for first.