David Fermani

Forza Auto Salon

I had the pleasure of sitting in on my 2nd 3M Large Panel & Spot Repair training class & I’d like to share some of the highlights that took place. 1st of all, I’d like to give a special thanks to 3M’s Sr. Account Rep Louis Federico for responding to the need for training at one of my largest Direct Repair Shops here in S. Florida; Maroone Collision. Maroone repairs all makes & models and is factory certified for Mercedes & Land Rover (very strict compliance). Most shops, mostly because of training & time limitations, really fail to produce the final finish that should exist when restoring a vehicle to pre-accident condition. 3M has come out with a system called their Perfect-It 3000 series that allows shops (and enthusiasts) to produce a flawless, swirls free finish.

Here are some pictures of the carrying case for the entire kit. Really cool!!

This 4 step system is great for both spot repair as well as complete panel finishing. Below are some pictures of the steps in the system:

Step 1 – Sanding

1st the surface is cleaned with 3M surface prep aerosol cleaner. This removes any wax or debris that might be on the surface that could hinder the performance of the products used in the following steps.

The entire panel or desired areas are 1st dry sanded with 3M 1500 grit sand paper via DA sander. This is used to quickly flatten most orange peel as well as dirt particles on top of the finish.

Step 2 – Compounding

Next, the same area is wet sanded with 3M Trizact 3000 grit paper via DA sander. This refines (knocks down) the 1500 sand scratches originally installed and actually gives off the appearance of a semi-polished surface. Sanding wet allows the paper to smoothly glide across the finish and more uniformly refine the surface.

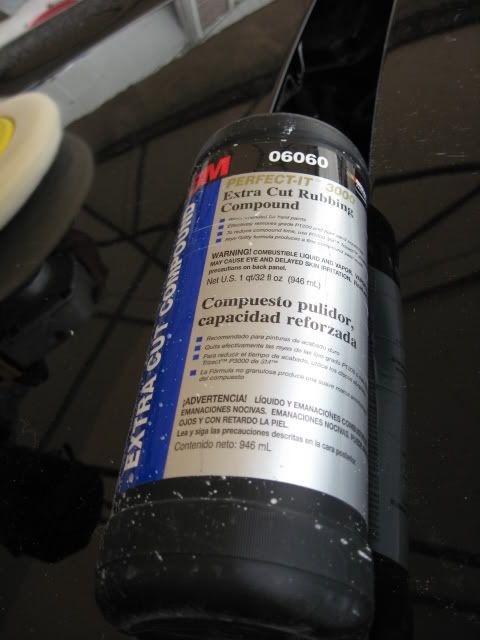

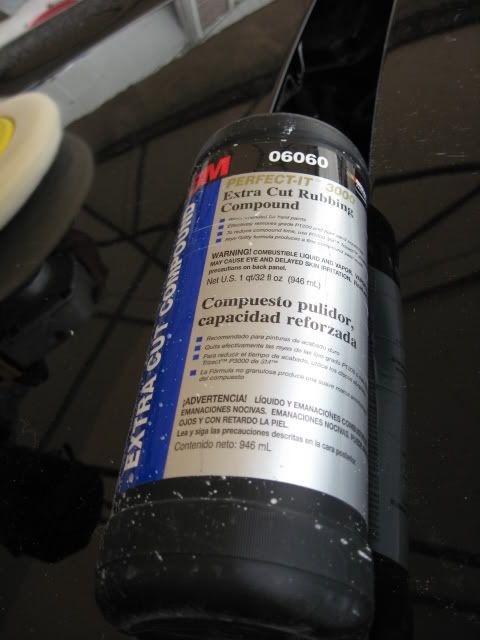

Next, 3M Extra Cut Rubbing Compound is buffed via a rotary buffer with wool cutting pad. Suggested buffer speed = 1400-1800 RPM. You’ll notice again the compound leaves the finish with a more polished look.

Step 3 – Polishing

Next, 3M Swirl Mark Remover is buffed via rotary buffer with foam polishing pad. Suggested buffer speed = 1400 – 1800 RPM. This removes the swirls created by the compound, but also leaves very faint traces of holograms that can usually be detected on dark colored vehicles. On lighter colored vehicles, it can be very difficult to detect swirls and therefore may not need further swirl removal. *Swirls were noticeable on the black vehicle after this step*

Step 4 – Swirl Elimination

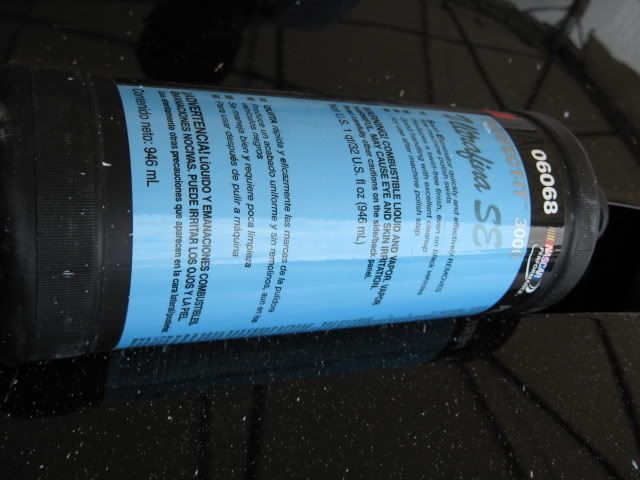

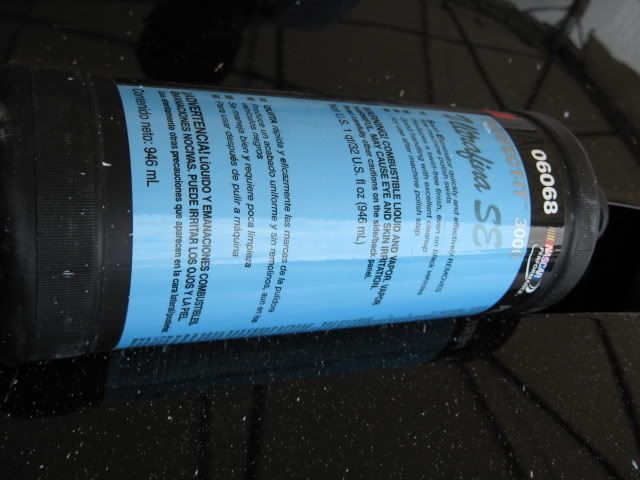

Finally, 3M Ultrafina is buffed via rotary buffer with final finishing pad. Suggested buffer speed = 1400-2000 RPMs. This polished is designed to be “left wet� upon final finishing and is to not be over-buffed/buffed dry. This product/pad will insure that the finish is 100% swirl free without the use of any fillers.

Here are some pictures of the carrying case for the entire kit. Really cool!!

This 4 step system is great for both spot repair as well as complete panel finishing. Below are some pictures of the steps in the system:

Step 1 – Sanding

1st the surface is cleaned with 3M surface prep aerosol cleaner. This removes any wax or debris that might be on the surface that could hinder the performance of the products used in the following steps.

The entire panel or desired areas are 1st dry sanded with 3M 1500 grit sand paper via DA sander. This is used to quickly flatten most orange peel as well as dirt particles on top of the finish.

Step 2 – Compounding

Next, the same area is wet sanded with 3M Trizact 3000 grit paper via DA sander. This refines (knocks down) the 1500 sand scratches originally installed and actually gives off the appearance of a semi-polished surface. Sanding wet allows the paper to smoothly glide across the finish and more uniformly refine the surface.

Next, 3M Extra Cut Rubbing Compound is buffed via a rotary buffer with wool cutting pad. Suggested buffer speed = 1400-1800 RPM. You’ll notice again the compound leaves the finish with a more polished look.

Step 3 – Polishing

Next, 3M Swirl Mark Remover is buffed via rotary buffer with foam polishing pad. Suggested buffer speed = 1400 – 1800 RPM. This removes the swirls created by the compound, but also leaves very faint traces of holograms that can usually be detected on dark colored vehicles. On lighter colored vehicles, it can be very difficult to detect swirls and therefore may not need further swirl removal. *Swirls were noticeable on the black vehicle after this step*

Step 4 – Swirl Elimination

Finally, 3M Ultrafina is buffed via rotary buffer with final finishing pad. Suggested buffer speed = 1400-2000 RPMs. This polished is designed to be “left wet� upon final finishing and is to not be over-buffed/buffed dry. This product/pad will insure that the finish is 100% swirl free without the use of any fillers.