Todd@RUPES

Just a regular guy

It wasn't long ago that DA polishers were used for light-duty polishing and/or waxing only. If you wanted serious paint correction you had no choice but to use a rotary buffer, a rock's n' bottle compound and a heavy-cut foam or wool pad.

Technology, in both polishes and pads, have allowed DA polishers to significantly close the heavy-cut performance gap. Pads have become smaller in diameter and thinner in design allowing them to more efficiently transfer the motion of the machine the paint.

Additionally, we have seen unique materials such as microfiber and short-cut wool pads make their way into the DA polishing world. With the ability to cut out coarse, P1500 grade, sand marks completely from paint, DA Polishers are now capable of removing extremely severe defects in a relatively safe manner.

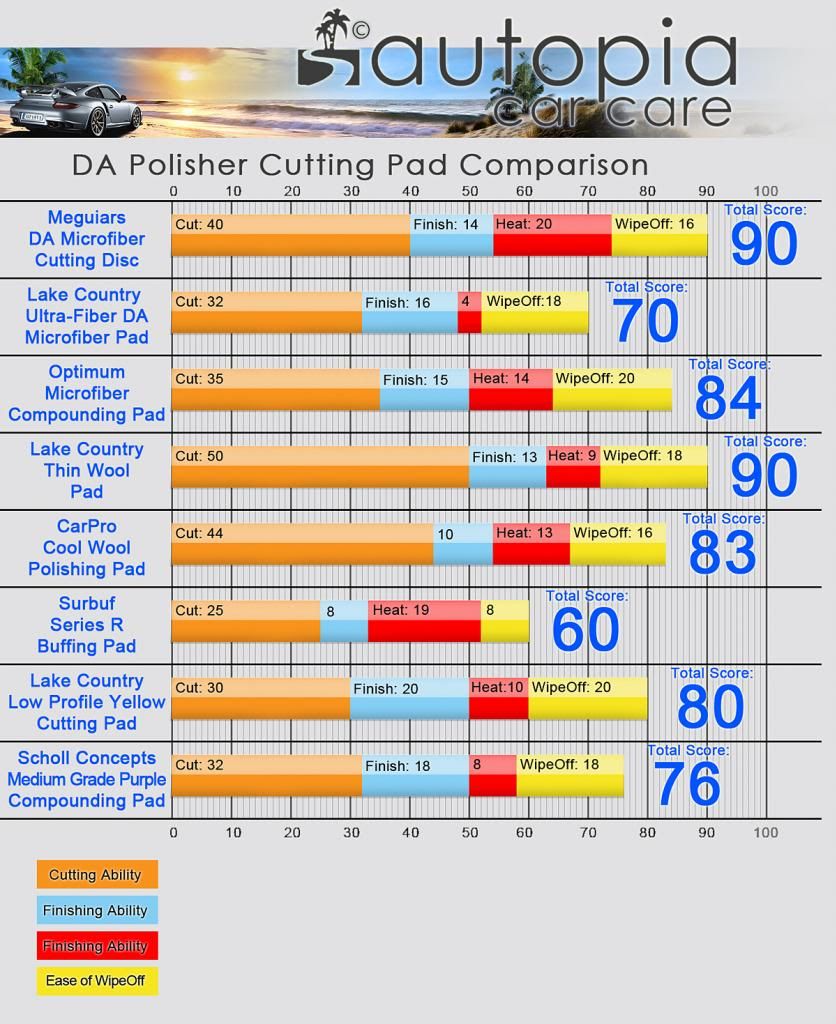

Scoring:

The DA Cutting Pads in this test will be ranked, and scored, on their ability to correct the paint finish, how well they finish, the amount of heat they produce, and how easy to the product is to wipe off after use.

The best in each subject will be given the maximum point total per category. The remainder will receive points based on performance relative to the best performing product.

Correction Ability: How well the pads, in combination with the polish, remove the P1500 grade sand scratches from the paint finish. Since the primary goal of a cutting pad is to remove surface defects, this will be the most heavily weighted performance category worth a total of 50 points.

Finishing Ability: Also important to how well a DA Cutting Pad performs is the quality of finish it leaves behind. While some level of surface scouring/haze is to be expected, it cannot be so much that an additional step must be performed prior to final polish. This category is worth 20 points.

Heat: Heavy polishing requires friction to remove material. Heat is a by product of the friction (in layman's terms). All machine polishing creates heat, however different pad designs will dissipate heat faster then others, keeping the surface temperature lower. Because excessive heat can damage the paint and underlaying material this category is worth 20 points.

Wipe Off: The way a pad works with a polish can greatly effect how easy to the polish is to remove from the surface. Pads that absorb a lot of lubricant or move too much air can dry the product on the paint, making removal difficult. This is the least important part of the write-up and worth only 10 points.

Although not weighted (because it is neither bad nor good) the way that the polish would break down was observed through out the process. Some pad's caused the product to break down quickly, delivering the majority of the cutting power upfront. Other pad's would break the polish down slower, allowing for a smoother, longer cutting action.

The Test Track:

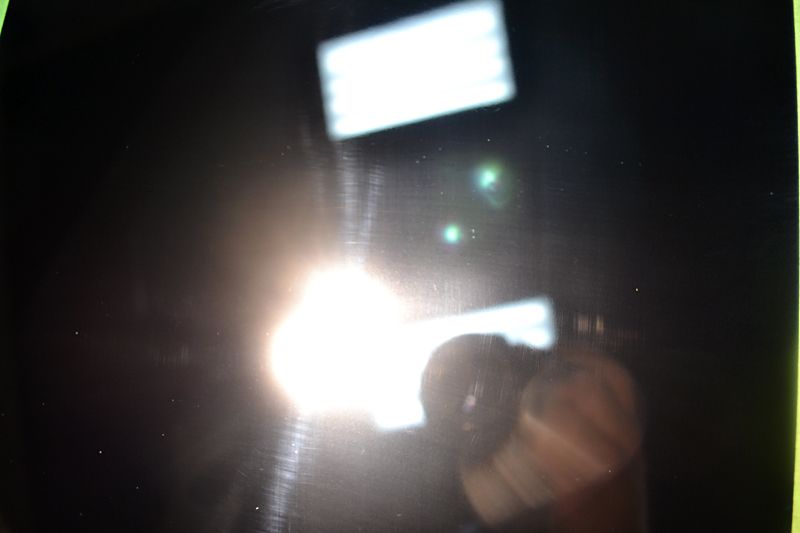

A large hood, divided into eight equal sections will serve as our test track. The paint finish on this hood is very soft, which allows these DA cutting pads level the paint quickly. In order to compensate for the soft paint the hood was sanded with Meguiars Unigrit 1500 grade sandpaper on a DA polisher.

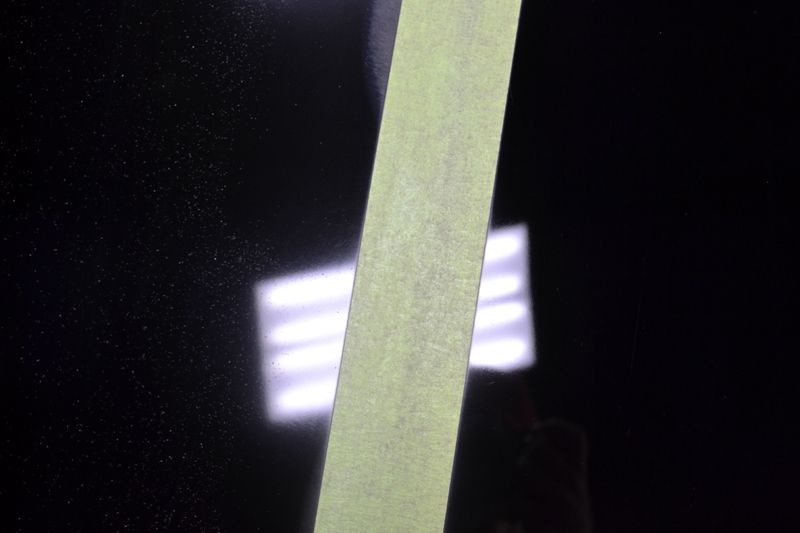

The hood was sanded with Meguiar's P1500 Unigrit Sandpaper to test the limits of each pad.

When illuminated with a Brinkmann Swirl Finder Spot Light the finish appeared hazy with little reflection.

The Test:

The first manner of testing was to select a polishing compound that is versatile and would equally well with all of the pads. This polishing compound would have to offer good cutting power to allow the pads to work AS WELL as having a good finishing ability so the truth finish of the pad could be accessed. Looking back at our recent 1-Step Polish Showdown, BLACKFIRE SRC Compound fit the bill perfectly.

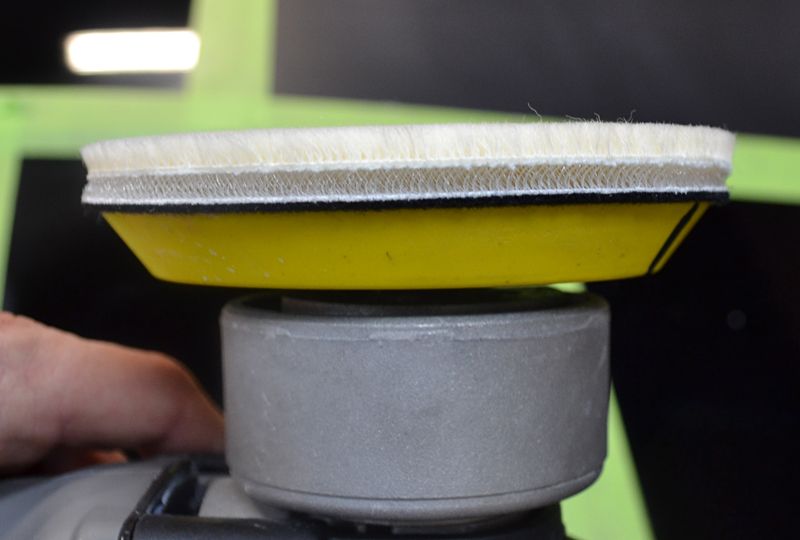

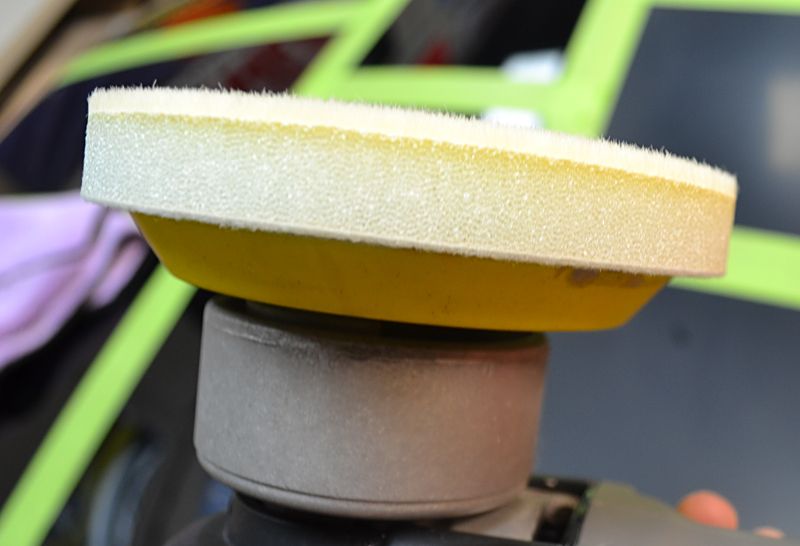

The tool used to apply the polishes was a Porter Cable 7424 XP. Decades after introducing the world to DA polishing, the Porter Cable remains one of the most popular and reliable machines available. Given the popularity over 5 to 6-inch polishing pads, all pads used in this test were designed to fit this parameter and attach to a 5-inch backing plate.

2 Polishing Passes- Some pads work better when primed or seasoned with polish while some pads work better fresh. In order to "meet in the middle" two polishing passes were performed back-to-back. For the first pass, an X was of BLACKFIRE SRC Compound was drawn across the pad to help prime it as it worked. For the second pass, three dime-sized drops were added around the outer third of the pad.

After the first pass the polishing temperature was assessed. Each pass was limited to 2 minutes in duration, should all 2 minutes be needed. The difference in correction between first pass and the second pass would give us a good indicator of whether the pad preferred to be primed.

Meguiar's DA Microfiber 5-inch Cutting Disc

Meguiar's re-wrote the rules on DA correction when they introduced their highly-engineered DA Microfiber Disks. The short-nap microfiber allows more of the polish to work at any given time and takes advantage of the small 5/16th-inch orbit created by standard dual-action polishers.

The Meguiar's DA Microfiber Cutting Disc features the longest nap and moderate density compared to the other microfiber pads in this comparison.

The Meguiar's DA Microfiber Cutting Disc features a foam backing that is also middle of the road compared to the other microfiber pads in this test. It features minimal overhang on the Lake Country Flexible DA Backing Plate although Meguiar's recommends using a Meguiar's DA Backing Plate for maximum pad life.

As the first pad tested, Meguiar's DA Microfiber Cutting Disc set the bar high. It was extremely easy to use and produced a very long buff time which continued to cut the entire 2 minutes of the first pass. Once primed with the product, the Meguiar's DA Microfiber Cutting Disc really came into it's own, eliminating the remaining defects easily and with time to spare!

Additionally Meguiar's keep the surface temperature fairly low, never reaching more than 87.4 degrees (only 10 degrees warmer then the test temperature). BLACKFIRE was easy to wipe clean after the testing. Compared the other microfiber pads in this test, the Meg's Cutting Disc left the haziest finish, although it would still be easily removed with a finishing step.

Meguiar's only raised the surface temperature by 9.8 degrees despite polishing with speed 6 and using firm pressure.

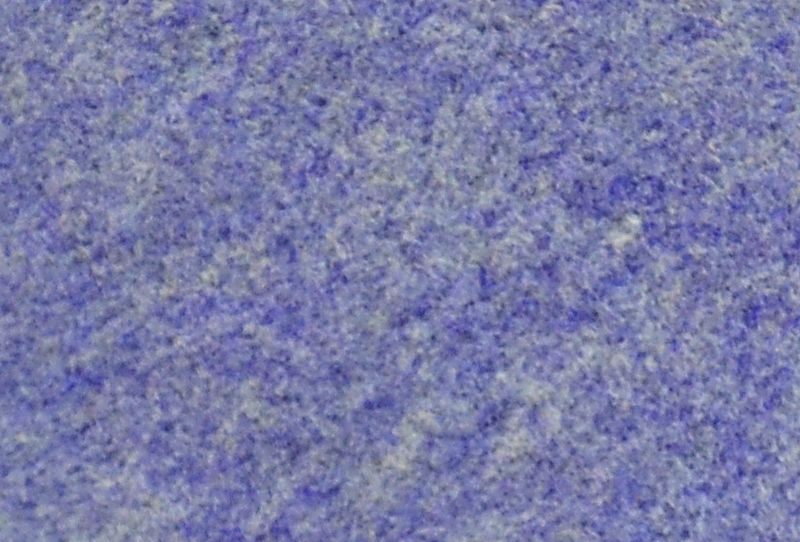

Meguiar's DA Cutting Disc completely removed all traces of sanding, including the 1500 grade texture. This disc offered excellent defect removal and leveling ability while leaving behind a noticeable, although not excessive, polishing haze.

Lake Country 5 1/4 Inch Ultra-Fiber Dual Action Microfiber Pad

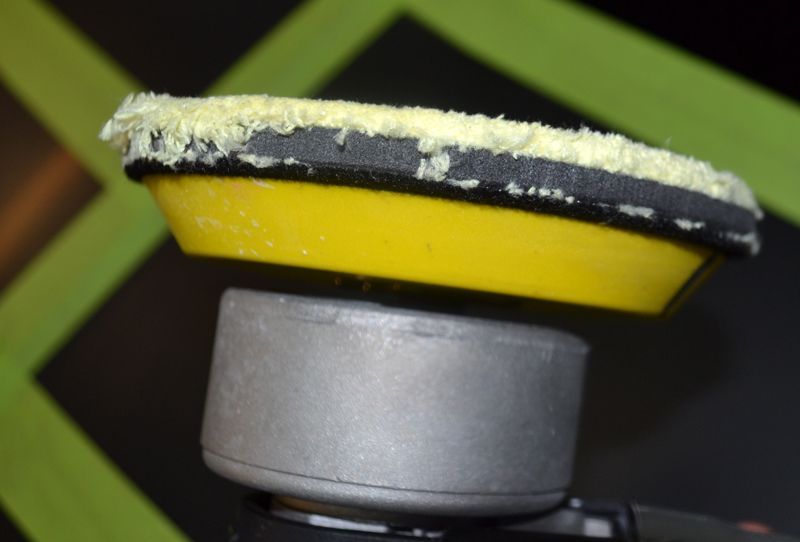

Lake Country Ultra-Fiber pads come in two designs. The dual action version which features a thin, hard foam backing and a rotary version which features a thick soft foam backing to easy contouring.

The Lake Country Ultra-Fiber DA Microfiber Pad featured the shortest and densest nap of any of the microfiber pads tested.

It also had minimal overhang for maximum polishing power and the firmest, thinnest backing material. In theory this should offer improved cutting power and a higher surface temperature.

With the excellent performance of the Meguiar's DA Cutting Disc, the Lake Country Ultra-Fiber DA Microfiber Pad had a lot to live up to. Out of all the microfiber pads test, the Ultra-Fiber clearly had the fastest rotational speed. Unforunately, the speed did not equate to polishing power as the Ultra-Fiber pad did not remove all of the sand scratches.

When loaded with additional product for the second pass, the Ultra-Fiber pad lost cutting ability, suggesting this pad does not require priming for maximum effect. While the BLACKFIRE SRC Compound was easy to remove after both sessions, surface temperatures reached a high of 126.1 degrees, showing a 42.7 degree increase, the highest recorded.

It appeared that combination of the wet BLACKFIRE compound and short nap caused the microfiber to lay flat, reducing the polishing ability and preventing the pad from dissipating heat efficiently.

Sanding marks littered the surface after 2 2-minute passes. Ironically, the Ultra-Fiber Microfiber Pads created the highest gloss and a haze-free finish.