Peugeot said:

Hi Roger,

I've been pretty disgusted with the whole "leather care" business. All adjectives and fuzzy warm prose and no science. Your post has inspired me to try again.

If it isn't too much trouble, can you elaborate more on two subjects:

1) Wetter than Water hydrator

What is it? How to get it?

2) fatliquor replenishing

How it is done? Products?

It's one thing to keep a set of skins maintained since new and I've seen great results with a disciplined standard treatment regiment with many products. But to bring back seats that have been neglected is a whole 'nuther kettle of fish!

Thanks again for addressing a subject which has gotten virtually zero serious attention as far as I've been able to find. And I've looked - from every detailing site to manufacturer's sites to the Smithsonian and other groups that seek to preserve historical artifacts.

Thank you for your interest in the science and logic of leather softening. This is one of the 21th Century technical breakthroughs in leather care. Bringing you back to the principle practice by modern tannery with the same result – if leather is able to be hydrated, it will be able to be fatliquor replenished to as soft as you wish.

“Wetter than Water” – It’s to Ease Away the Interfacial Tension:

When water or liquid is applied onto the surface of the leather; there is this interfacial tension between the liquid and the surface of the leather.

Pure water when dropped onto average smooth leather surface will see that it pools or even rolls on the surface and eventually evaporates or otherwise takes a long time to eventually seep through the surface.

Compare it when a “wetter than water” hydrator is dropped onto the same surface, it will immediately spread out and seep through the surface much quicker, otherwise spread out on non-absorbent surface.

It is this surface active agent in the hydrator that does this penetrating work; the characteristic of a hydrator for being “wetter than water”.

The foam we see in the bottle when shaken up is all the power of “wetness” derived.

Water used as a conditioner to soften leather during the staking process in a modern fast paced tannery is of this category of “wetter than water” water too.

“Wetter than Water” – It’s acidic with a pH Value of 3.3:

All water based solution would have a pH reading when read with a pH meter or litmus paper.

This water based leather-safe hydrator is calibrated to pH 3.3 that falls in line with the lower end of the leather neutral pH range of 3 to 5.

“Wetter than Water” – It’s Leather-Safe:

Leather is in fact a compound material; its protein fiber can hold up to 30% of other related leather chemistry.

The stability of the leather depends on the protein fibers that have the tendency to shift poles from positive to negative.

Leather protein fibers when acidified below its isoelectric point cationized positive (+).

While the other leather constituents including the fatliquor remains constantly anionic negative (-).

Thus the molecular hydrogen bonding takes place like the principle of magnet or electrostatic painting, unlike poles attracts.

The reverse takes place when the protein fibers slowly shift negative (-), with influence from any alkaline solution above its isoelectric point averaging at pH 4.

So water at pH 7 becomes a negative influence for the leather, that’s why water damage resulted in stiffness when dry; the cause is the leaching out of fatliquor that breaks the hydrogen-bonding with the leather protein fiber.

The above explains why water is bad to condition leather; the culprit is in its pH value that causes shifting of poles.

All purpose cleaners used for leather cleaning damages leather fibrous structure through stitching holes, micro-cracks and perforation and these are the places that starts to fail; where round holes becomes elongated and start to split through the finish as well.

In such situation a pH 2.0 acidifier is further used to rectify the alkaline overexposure prior to hydrating at pH 3.3 to stabilize the protein fiber positive (+).

“Wetter than Water” – It’s Purpose of Usage:

It’s for lowering the interfacial tension between the protein leather fibers and its constituents.

It’s for hydrating dried, stiffed or shrunk leathers to separates the crushed, stick together fibrils and relaxes them in the inter-fibrillary leather structure for effective distribution of the Fatliquor-5.0.

It’s for charging the leather protein fibers below its iso-electric point positive to hydrogen-bond with the ionic negative charged Fatliquor-5.0.

It’s for facilitating colloidal water movement within the leather structure during the wicking process to move soiling particulates to the surface.

It’s for reactivating the dormant dyestuff to resurface thus reducing the contrast between the color coat and the leather crust.

It’s for reducing the interfacial tension to eliminate blotchiness when dry especially absorbent leathers.

It’s for facilitating better finish penetration during refinishing thus providing good surface properties, especially the uniformity of surface dyeing during aniline refinishing.

Fatliquor – What is it?

Fatliquor-5.0 is an anionic negative (-) charged micro emulsion derived from specially selected fat and oil that gives a milky appearance similar to fresh milk.

It is water based where the ionic fat and oil are encased in a molecule of water.

The average molecule of oil is usually larger than water; in this case it is reversed where the molecule of fat and oil is reduced into such size that it is encased by the water molecule.

The average fatliquoring process in the tannery takes place at an average temperature of 125 degrees Fahrenheit for the fat and oil to remain stabilized as an emulsion.

While else the fatliquor in a bottle stabilize at room temperature, chilled from the fridge and still looks like fresh milk without separating its fat and oil from the water like other outdated conditioner.

The ability for the fat, oil and water to stay intact prior to penetrating the inter-fibrillary leather structure is of prime characteristic of a fatliquor; it is only on contact with the positive charged protein fibers that the encasing water is break free.

The fat plumps the leather with fullness; the oil lubricates the individual fibrils like inter-connecting hinges allowing the sliding over of one another smoothly when the leather is compressed and stretched when flexed.

The principle of fatliquoring is the same whether it’s, the first time in tannery or second time in the retanning or the third time to fatliquor replenishing it on finished leather goods.

The whole idea is to distribute a very small amount of fat and oil over a very large surface area of the leather fibrils that acts as interconnecting hinges to give suppleness to the leather.

This would include the reverse suede sides, so a product that cautions on suede logically is or was never used to soften leather in the first place.

Fatliquor Replenishing – How is it done?

It’s done in conjunction with the hydrating process, unless the leather structure is able to be plump with hydration; it is futile to fatliquor it.

It is done the non-immersion method by spraying and spreading with a foam brush; unlike the first or second time in the tannery drum immersion method.

It is recommended to be done after successful hydrating while the leather is damp for the simple reason to have an even distribution of the fatliquor to the entire leather fibrous structure.

Advance technique utilizes facial tissue paper acting as reservoir to hold both the hydrator and the fatliquor in similar fashion for the slow absorption through the non-absorbent leather finishes.

Transparent plastic cling wrapper is also used to control evaporation, smaller items can be put is zip lock bag or plastic containers for similar reason.

Unlike hydrating which is one way for the hydrator to plumps the leather; in fatliquor replenishing the technique is to allow the water to evaporate off the leather to make spaces for further application until the leather structure is saturated.

Fatliquor Replenishing – Why it’s done?

It’s for replenishing original fatliquor that diminishes thru evaporation as VOC (volatile organic compound) gases from sun-bleaching, ageing and heat; leaching through breaking of hydrogen-bonding from water damages and alkaline cleaning solutions.

It’s for lubricating the leather fibers so that after drying they will be capable of sliding over one another smoothly.

It’s for softening the leather fibrous structure with stretchability, compressibility and flexibility, while enhancing its rip tensile strength greatly.

It’s for relaxing coarse breaks, creases and wrinkles to provide drapes, suppleness and prevents cracking.

It’s for helping to keep leather at its optimum physical performance and prevent premature ageing.

How to get it?

Simply just email me of your interest.

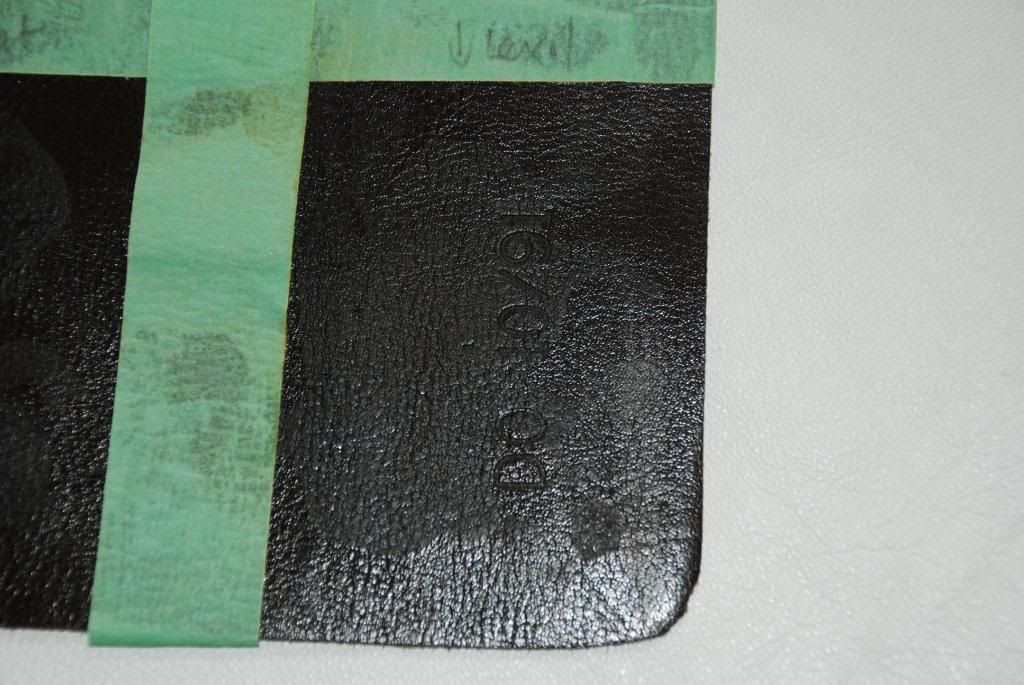

By the way please show some pictures, so that help will be more specific.

Further questions are welcome!

Roger Koh

info@leatherdoctor.com