imported_Detailing Technology

New member

In reading about the Kevin Brown Process, I have come up with a basic understanding, but am still waiting for the final document to be released.

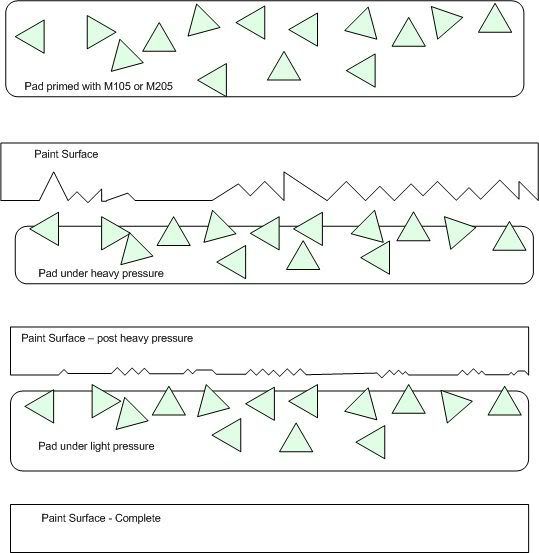

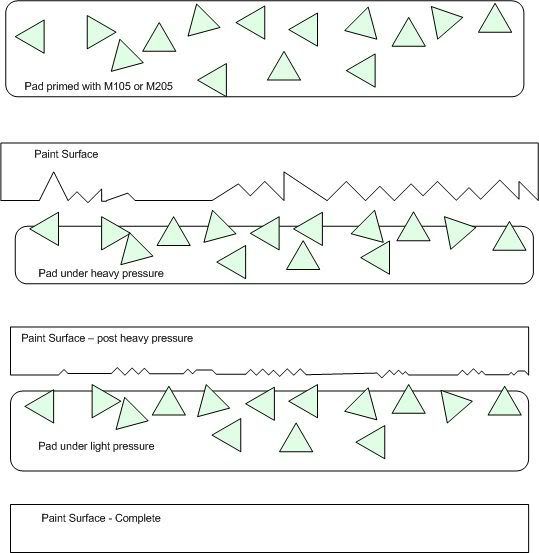

I believe the idea is to turn the foam pad into a sheet of variable grit sandpaper. Non-diminishing grit is housed in the pad, then via pressure it is extruded though the pad on to the surface.

Am I correct in my representation below?

A. Pad Primed with media

B. Surface shown with major defects

C. High pressure is applied to the pad, thus extruding abrasives and removing deeper defects

D. Pressure is gradually releived, thus reducing the amount of abrasive protruding hence polishing a finer level of defects

E. FINISHED

Is the idea of spraying water onto the surface to induce capilary action to draw more abrasives to the surface of the pad for more cut?

Seems we have gone full circle with polishing processes. This takes me back to the days of sanding primer with a "mudder" which could carefully remove mass amounts of material quickly in professional hands.

I believe the idea is to turn the foam pad into a sheet of variable grit sandpaper. Non-diminishing grit is housed in the pad, then via pressure it is extruded though the pad on to the surface.

Am I correct in my representation below?

A. Pad Primed with media

B. Surface shown with major defects

C. High pressure is applied to the pad, thus extruding abrasives and removing deeper defects

D. Pressure is gradually releived, thus reducing the amount of abrasive protruding hence polishing a finer level of defects

E. FINISHED

Is the idea of spraying water onto the surface to induce capilary action to draw more abrasives to the surface of the pad for more cut?

Seems we have gone full circle with polishing processes. This takes me back to the days of sanding primer with a "mudder" which could carefully remove mass amounts of material quickly in professional hands.